In the rotor system of the rotating machinery of the generator, the parts that are prone to EDM discharge are the bearing surface of the radial bearing and thrust bearing, the working tooth surface of the gear coupling and the sealing surface of the floating ring. Due to various conditions in operation (such as load, temperature, lubrication status and rotor vibration, etc.), these parts may reduce the oil film and air gap resistance. Spark discharge is caused in these parts. The rotating shaft must be lubricated in a certain way so that the rotor and the bearing are not in direct contact, that is, the entire rotor has oil film insulation between the stator and the rotor at high speed. Since the rotor has resistance to the ground, once it is charged, the voltage to the ground will be established, and when the voltage rises to a certain value, it will break down in the area with small resistance and spark discharge will occur. Metal particles are melted in the discharge area, and very small pits are formed on the metal surface. The accumulation of pits makes the surface rough and tarnish, and if it occurs on the bearing, it will produce pure mechanical wear; Molten metal particles enter the lubrication system, contaminate the lubricant, the lubrication performance of the whole lubrication system deteriorates, and the lubricant containing a large number of metal particles will reduce the oil film resistance and accelerate the progress of EDM erosion; Local high temperature is generated in the bearing bearing area, which destroys the oil film, burns out the metal, increases the wear, and eventually causes serious friction damage.

For radial plain bearings, the development of bearing electric pitting will cause serious corrosion on the babbitt surface, which will not only change the original clearance of the bearing, but also lead to the reduction of the surface finish of the bearing surface scrapes and scratches, local high temperature and burns. The wear of babbitt alloy on the surface of high-speed light-load bearing will cause some bearing blocks to lose the preload effect on the rotor journal, and the rotor will easily induce the oil film eddy when rotating, resulting in the instability of the rotor system. The unstable oil film, in turn, will cause a sharp decline in the bearing oil film resistance, so that more shaft current passes through the area, exacerbating the electric spark action, and motivating each other, eventually leading to the damage of the bearing or rotor system.

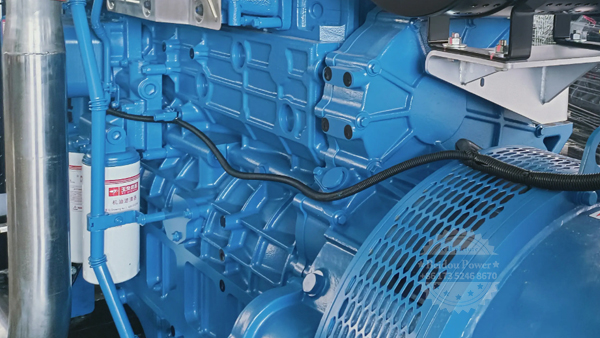

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-25-2024