According to the layering method of wrapping tape, insulation wrapping can be roughly divided into three types: layering, layering (half layering) and flat wrapping. When wrapping, the wrapping method of the tape should be distinguished according to different parts and needs. The dip Angle of the tape should be consistent when bandaging, so that the packaging can be accurately mastered and the insulation void and gap can be avoided.

(1) When bandaging, the tape should be slightly pulled tight, and the tape should be kept flat without wrinkles; The presence of air gap can be reduced by matching the coating with paint.

(2) Different types of tape, should use different performance and requirements of the interlayer paint or glue, especially the manufacturer has specified varieties. The interlayer paint should generally be brushed first and then wrapped, and can not be wrapped first and then painted.

(3) Flat winding method According to the use, there can be 1 ~ 3mm gap between the tape, but the tape can not generally be overlapped before and after, and the docking method should be used, especially the wrapping of the anti-halo belt on the surface of the wire rod, and the wrapping should be completed as far as possible, even if the docking, the docking part should also be placed on the narrow surface of the wire rod (that is, the part that does not contact the iron core surface).

(4) Some of the coated electrical part appearance (such as joints) is not smooth, should use epoxy putty to pave it flat or smooth, and then wrap the insulation tape, should try to eliminate the gap between the insulation tape and the conductor.

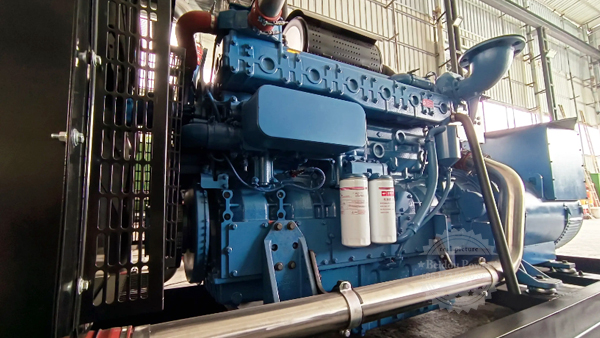

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-20-2024