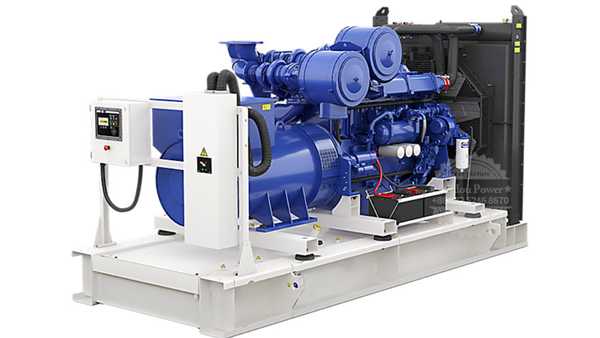

Now the important equipment generator set for the computer room, with the different requirements of other equipment for power supply, there is a great development. Combined with their own experience, the direct selling network has made a systematic summary of its new characteristics and development trend by referring to relevant data. It is for reference for equipment room design, complete sets, and purchase. I hope it gives you some valuable information.

1. New features of diesel generators

The technical level of diesel generator set is closely related to the technical development and level of diesel engine, and diesel engine is often taken as an important content to measure and evaluate the performance of diesel generator set. Because of the daily use and maintenance and regular work, mainly diesel engines, so the excellent performance of diesel engines is the solid foundation of modern generator sets.

(1) Constantly improve the mechanism, using turbocharged intercooling and other technologies.

Recently, foreign diesel generator sets using diesel engine power greater than 50kW, are generally used turbocharging technology to improve the specific power, while using different cooling technology, combined with multi-valve technology, so that the specific power of diesel engine to further strengthen. Its high specific mass value can reach 1.98kg/kW, while the specific mass of ordinary diesel engines is 8.0 ~ 20kg/kW, which shows a wide difference. Due to the strengthening of specific power, the material properties of air intake system, fuel supply system, piston group and crankshaft connecting rod mechanism must be continuously improved and improved, and the production technology level is also put forward higher requirements.

(2) The wide use of high-speed diesel engines. Medium and small power units (2000kW or less) generally use high-speed diesel engines, from the past decade of units ordered around the world, 80% of the speed of 1500r/min diesel engines, so that the overall performance of the unit has been improved.

(3) The use of electronic injection technology, electronic governor, electronic hydraulic governor. The power supply quality of the unit is improved and the pollution of the exhaust to the environment is reduced.

(4) The use of dual combustion technology. The diesel engine fuel system is designed to burn both diesel and natural gas to improve its adaptability.

(5) High manufacturing precision, close to zero tolerance production, good mechanical properties. The first overhaul brick transport time is 25,000 ~ 30,000 hours, and the general unit is within 20,000 hours.

(6) The use of high pressure common rail fuel supply system, through the precision electronic control of fuel injection device, you can freely control the injection time, injection amount and injection pressure, to achieve the rated limit to reduce diesel engine combustion noise, effective control of diesel engine harmful gas emissions. And can obtain obvious economic benefits. The fuel consumption is reduced, such as the fuel consumption rate of Mercedes-Benz MUT unit is 198g/kWh, the surface noise of the unit only reaches 106dB, reduces the exhaust pollution, increases the sudden loading capacity, and 70% can be loaded within 2 ~ 4s. The general unit is loaded at about 15s.

(7) Cold start performance, in the absence of an auxiliary device and at -20C elbow can be successfully started with an auxiliary device can be successfully started at -50C.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-30-2024