Taking the ordinary process generator to replace the lower ordinary wire rod (tin welding head) as an example, the main process of replacing the wire rod without lifting out the rotor maintenance is as follows (some generators need to lift out the rotor to replace the wire rod):

1. Prepare.

1) Remove the cover of the generator upper frame at the corresponding part of the wire rod to be replaced.

2) Remove the corresponding generator stator upper wind baffle; Remove the lower air baffle as required.

3) Determine the magnetic pole to be pulled out, remove its corresponding magnetic pole connection, and damping ring connection head.

4) Pull out the corresponding magnetic pole.

5) Determine the upper and lower wire rods to be pulled out and number them one by one.

6) Spare wire rod test.

2. Remove the wire rod.

1) Remove the insulation box of the stator wire rod joint related to the replacement wire rod, weld the wire rod joint and head cover.

2) Remove the end of the corresponding wire rod and the binding rope of the hypotenuse, and the binding rope of the end hoop, and take the exit pad and the hypotenuse pad.

3) Pull out the slot wedge, oblique wedge and cushion bar to be pulled out.

4) Take out the upper wire rod and the interlayer pad.

5) Take out the lower wire rod and the bottom pad.

6) Iron core groove cleaning, spray with low resistance semiconductor paint if necessary.

3, back the wire rod.

1) Lower the bottom pad and the bottom wire rod; The test passed.

2) Install the lower wire rod bevel edge pad, binding and binding with the end hoop.

3) the middle pad bar and the upper line bar; The test passed.

4) The upper pad bar and slot wedge, diagonal wedge.

5) Tighten the slot wedge; The test passed.

6) Install the wire rod joint and head cover, weld the joint, and pass the joint resistance test.

7) Install the connector insulation box.

8) Install the mouth pad and hypotenuse pad, the end and hypotenuse rope, and the lower part of the groove wedge rope.

4. After all the work is completed, the end of the winding should be sprayed with surface coating paint according to the process requirements. Reinstall the rest of the components in the reverse order of disassembly.

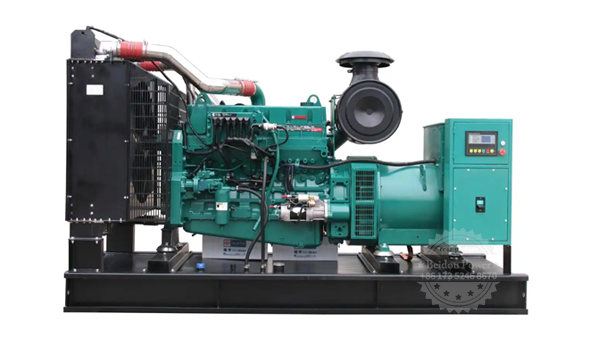

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Dec-23-2024