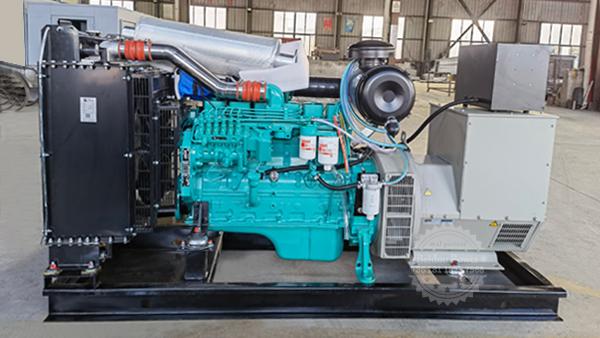

The wear fault of Cummins generator is mainly caused by vibration. In addition to the vibration of the equipment itself, the instability of the surrounding environment can also affect the equipment. Next, we will explain how to reduce the vibration of a Cummins generator.

Users are advised to use shock absorbers when installing Cummins generators. According to the installation hole on the Cummins generator chassis, the user should place the Cummins generator on a flat and solid foundation (shock absorbers should be fastened on the concrete foundation with expansion bolts); This can reduce the vibration and impact on the building during the operation of the Cummins generator, so it is not recommended to adopt shock absorption measures without special requirements.

In addition to connecting the Cummins generator to the foundation by means of shock absorbers, the * components of the Cummins generator shall also be connected by means of flexibility. For example, smoke exhaust pipes are connected through corrugated shock absorbers; Exhaust pipe, inlet pipe, return pipe, distribution cable, etc. Flexible connections should also be made to reduce vibration of surrounding objects caused by Cummins generator operation.

Note the vibration protection requirements between the internal components of Cummins generator. The simple way is lubrication and maintenance, and friction between parts. As for the vibration of Cummins generator itself, we should find the fault in time and carry out maintenance. Only in this way, Cummins generator can reduce wear and ensure the durability and service life of Cummins generator.

Post time: Oct-27-2022