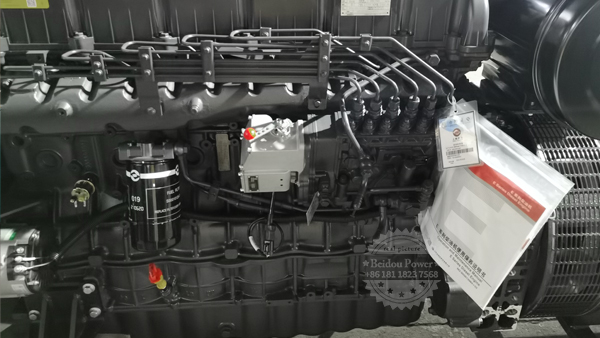

The generator fuel pump is the “heart” of the engine fuel supply system. The generator fuel pump is a device that continuously sucks fuel from the fuel tank and provides the fuel system with fuel with specified pressure and flow. Based on the function of the generator fuel pump, it can be known that the performance of the fuel pump will directly affect the working performance of the engine. Therefore, it is necessary to make corresponding preparations before using the fuel pump.

In order to ensure the normal use of the generator, debugging the fuel pump is the primary preparatory work. We must install and debug according to the fuel pump calibration data sheet on the special test bench. At present, most of the flowmeter method is used, and the specific steps are as follows:

1. Preparation before debugging. The fuel pump and injector have been debugged on the test bench, the generator is in good technical condition and has entered a hot running state; the fuel pump is correctly connected to the drive device, and the gear pump injects clean fuel; the throttle control rod is disconnected from the connecting rod, In order to be able to move freely; the tachometer is installed on the connecting device of the drive shaft of the fuel pump chronometer; check whether the instruments used (such as pressure gauge, tachometer, etc.) are normal.

2. Idle speed adjustment. Remove the plug from the cover of the PTG governor spring assembly. Adjust the idle speed of the generator by rotating the idle speed adjusting screw (600±20)r/min. After the idle speed adjustment, screw back the screw plug; for the generator fuel pump equipped with the MVS governor, the idle speed adjustment screw is located on the governor cover, and the lock nut should be tightened after the idle speed adjustment to prevent air from entering.

3. High-speed adjustment. Usually, when the fuel pump debugged by the test bench is installed, high-speed adjustment is not required. If adjustment is required, the method of increasing or decreasing the high-speed spring washer is still used; the speed at the disconnection point of the generator governor should be 20~40r/ min, to ensure that the governor will not limit the speed before the calibration speed; the maximum idle speed of the generator is generally 10% higher than the calibration speed.

I hope that the sharing of the above content can help you to debug and use the fuel pump more easily. Many users have difficulty in using and maintaining the generator set in the later period due to their lack of in-depth understanding of the generator. Therefore, a professional enterprise is required to provide technical support and guidance for the later use and maintenance.

Post time: Jul-18-2022