The diesel generator set is generally bought as a backup, so it has been in a state of standby waiting for use, but it is generally rarely used, and the generator is usually in a state of standby lack of detection, maintenance, etc., but the generator is an essential backup power supply, if it is found that the generator can not be used in an emergency, it is not very mad? The following will introduce the solution, in fact, it is possible to maintain the performance of the generator through regular maintenance means to achieve the purpose, and maintenance needs to understand the following parts.

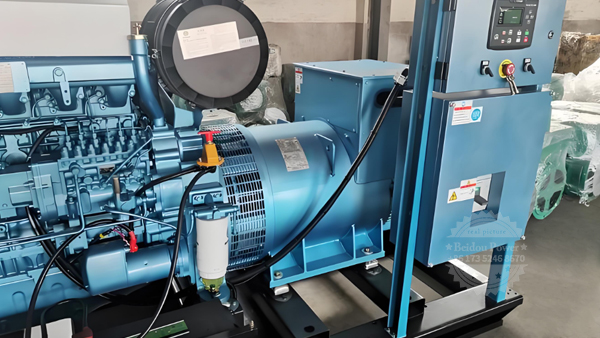

Diesel engines generally include: body, crank linkage mechanism, valve mechanism, fuel system, lubrication system, cooling system, electrical system.

Body: is the skeleton of the diesel engine, by which to support and install other components, including: cylinder block, cylinder liner, cylinder head, cylinder cushion, oil pan, flywheel housing, timing gear housing, front and back feet.

Crankshaft connecting rod mechanism: it is the main moving part of diesel engine, which can convert the energy generated by fuel combustion into mechanical energy through the piston, piston pin, connecting rod, crankshaft and flywheel. Including crankshaft, connecting rod, piston, piston pin, piston pin circlip, piston pin bushing, piston ring, main shaft, connecting rod, thrust bearing, crankshaft front and rear oil seal, flywheel, shock absorber, etc.

Valve mechanism: it is to open and close the inlet and exhaust valves regularly. Including timing gear, camshaft, pedestal, ejector rod, rocker arm, valve, valve spring, valve seat ring, valve guide, gas door lock block, inlet and exhaust pipe, air filter, supercharger, etc.

Fuel supply system: according to the needs of the diesel engine, the diesel fuel is supplied to the combustion chamber regularly and quantitatively. Including diesel tank, oil pipeline, diesel filter, fuel injection pump, fuel injector and so on.

Lubrication system: The lubricating oil is supplied to each moving friction pair, including oil pump, oil filter, pressure regulator, pipeline, instrument, oil cooler and so on.

Cooling system: The heat generated when the diesel engine is working is distributed to the atmosphere. Including water tank, pump, fan, water pipe, thermostat, water filter, fan belt, water temperature meter, etc.

Electrical equipment: It is the auxiliary equipment for starting, lighting, monitoring and operation. Including generators, starting motors, batteries, relays, switches, lines, etc.

Generator maintenance can be classified from the above parts and then carried out, the corresponding parts of the maintenance effect will be better.

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Mar-18-2025