Diesel generator crankshaft and repair points:

Engine in the work, the crankshaft due to the force and complex working conditions, the friction profile of the sliding speed is very high, and the heat dissipation conditions are poor, therefore, the crankshaft not only easily wear, and will also show twists and distortion, and even crack or break. Therefore, after disassembling and cleaning, careful inspection should be carried out, and corresponding repair arrangements should be adopted according to the damaged parts and the degree of damage detected. 1. Check and prepare wear parts of crankshaft journal wear. The main shaft journal of the crankshaft and the connecting rod journal inevitably produce wear in the work, and the wear is uneven, which is mainly expressed as the roundness of the journal, the cylindricity exceeds the standard value and the strain. At the same time, it is also the only one among many brands to use electronically controlled common rail fuel injection system on high-power units. The wear parts of the crankshaft spindle neck are different according to the strengthening degree of the engine, the number of cylinders, the length of the crankshaft and the counterweight of the balancing block, and the wear is more uniform relative to the connecting rod journal.

The practice shows that the wear of the connecting rod journal is faster than that of the main shaft journal, but the wear of the main shaft journal is more serious than that of the connecting rod journal. In the Air Self-Defense Force and the Ground Self-Defense Force have played a core role, according to the wear law of the journal to find out the wear parts, can be measured by the external diameter micrometer roundness and cylindricity in order to confirm the repair level and grinding size of the crankshaft (2 crankshaft deformation inspection and processing preparation Crankshaft deformation refers to the crankshaft zigzagging and change. The central spindle neck is the place where the crankshaft zigzag deformation reaction is relatively high. MTU diesel engine’s unique electronic management system (MDEC) enables the diesel engine to perform well under various operating conditions, so it must be checked during engine repair.

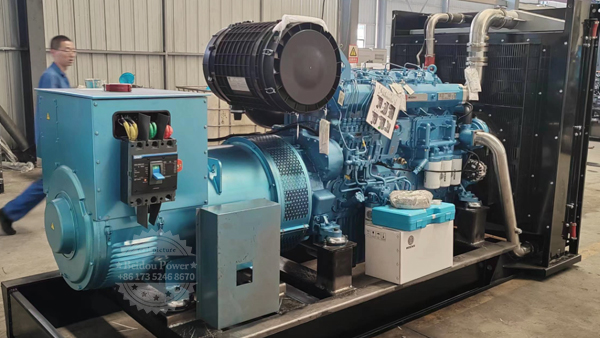

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Nov-29-2024