The method of eliminating the waste heat in the engine room of diesel generator set and cooling the engine room is determined according to the water source and weather conditions of the power station project, and is generally designed according to the following principles:

(1) When the water source is sufficient and the water temperature is low, the power station should use water-cooled type for cooling, that is, water is used as the refrigerant to cool the air in the diesel generator room. The condition of designing water-cooled power station is that there should be sufficient natural water source; Such as well water, spring water, river water, lake water, etc., or other water sources that can be used; Good water quality, non-toxic, tasteless, no bacteria to disease, no corrosion to metal; The content of inorganic matter and organic matter such as sediment in water should meet the standard requirements; Water cooling should be low, the difference between the temperature of the diesel generator room and the temperature of the water cooling water should be greater than 15 degrees Celsius, and the low is not less than 10 degrees Celsius. If the water temperature is high, the return air temperature difference is small, the air supply system is large, and the construction investment and operating costs must be increased.

Compared with other cooling methods, the water-cooled power station has the advantages of smaller inlet and exhaust air volume, so the inlet and exhaust ducts are smaller. The water-cooled power station is less affected by the atmospheric temperature outside the project, and can ensure the air cooling of the machine room in any season. The disadvantage is that the water consumption is large, limited by water source conditions, when the project does not have sufficient low temperature water source, it can not use this cooling method.

The cooling method of water-cooled power station can be water shower cooling method, that is, water washing air. Because the hot air in the machine room is directly in contact with the dripping water droplets, the cooling and cooling heat exchange effect is good, and the harmful dust in the air in the machine room can also be partially washed by the dripping water to purify it. Water-cooled power plants can also use the surface cooling method, that is, the hot air in the room is exchanged with the cooling water on the surface of the metal cooler. The advantage of this cooling method is that the cooling system can be flexibly organized, configured according to needs, and does not account for or less of the diesel generator room area. For example, some closed-cycle cooled diesel generator sets are equipped with nose radiators, which are generally not used in the closed power station room. The diesel engine cooling water can be changed to an open system, and the cooling water can be passed into the head radiator to achieve the effect of reducing the temperature of the machine room and eliminating the waste heat of the power station.

(2) When the water source is difficult or the temperature of the air imported from the diesel generator room in summer can meet the cooling requirements of the diesel generator room, air cooling or the combination of air cooling and evaporative cooling should be used. The air-cooled power station uses the low temperature air outside the machine room (generally about 5 degrees Celsius below the design requirements of the machine room) to increase the intake air volume, and applies the intake air and exhaust air to eliminate the waste heat in the machine room.

The air-cooled power station does not need a large amount of low-temperature water source, no cooling air supply system, simple ventilation system in the machine room, easy operation, large air intake and exhaust volume, more air changes per hour in the machine room, fresh and comfortable air. However, the fan capacity of the intake and exhaust ducts is large.

Evaporative cooling power station only needs a small amount of water, according to the diesel engine power calculation, generally no more than 1.5×1.36kg/h per kilowatt, no strict requirements for water temperature, than the air-cooled power station can reduce the air intake more than half, especially suitable for water difficulties, high water temperature areas. With the deepening of the research and experiment of evaporative cooling, evaporative cooling equipment is constantly improving.

(3) When there is no sufficient water source and the air inlet temperature cannot meet the requirements of the air-cooled power station, artificial refrigeration can be designed and a chiller with its own cold source can be used to eliminate the waste heat of the diesel generator room. The construction investment and operating costs of artificial refrigeration system are high, in winter or excessive season, the power station should make full use of the cold air outside the project for ventilation and cooling, so air cooling should generally be the main way to eliminate the waste heat of the power station. Diesel power station adopts automatic unit, after the realization of compartment, the staff on duty can generally not enter the machine room, and the high allowable temperature of the machine room cooling design can be designed according to 40 degrees Celsius.

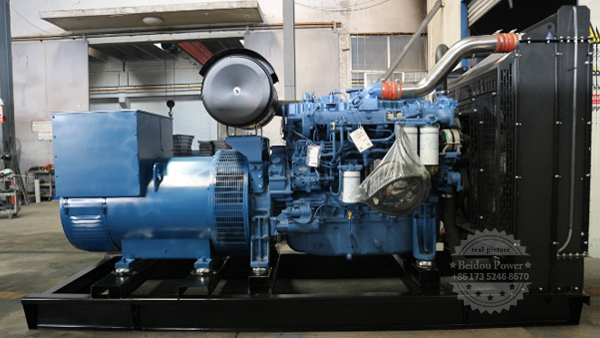

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jan-17-2025