In order to ensure uninterrupted operation of the diesel engine, the fuel coming out of the tank must be carefully removed of impurities. If the fuel is not filtered properly, the precision couple in the fuel injection pump and injector can quickly wear out or get stuck. Wear of precision pairs will cause uneven oil supply to each cylinder, increase fuel consumption and decrease power.

Two filters are generally installed in diesel engines. The first is a coarse filter, which is installed before the pump to filter out larger impurities. The second is a fine filter, which can filter out small impurities and is installed before the fuel injection pump.

Coarse filter is generally used mesh filter. Fine filters are usually paper and felt filters and high pressure slit filters.

First, paper filter type filter

It is mainly composed of three parts: filter element, shell and filter seat. The fuel is fed into the fuel filter by the oil delivery pump, and the impurities in the fuel are removed through the paper filter element, into the inner chamber of the oil filter cylinder, and then through the oil collecting chamber on the filter seat, leading to the injection pump. The filter seat is provided with an oil return connector, which is equipped with an overflow valve. When the fuel pressure in the fuel filter exceeds 0.08MPa, excess fuel is returned to the fuel tank by the oil return connector. The low pressure fuel line should be connected in the direction of the arrow on the seat. The sealing washer at the bottom of the filter element is installed in the spring seat, and the spring will close the sealing washer to the bottom of the nut to seal. The filter seat and the shell are connected by a pull rod, and are sealed by a rubber ring. The upper end of the filter seat is provided with a vent screw, which can be loosened to remove the air in the fuel filter in use.

Two, felt filter

The felt filter is mainly composed of a filter, a filter element and a filter cover.

The filter element is arranged in the filter body, which is composed of metal mesh, silk sleeve and felt filter, and the filter consists of 7 thicker pieces and 8 thinner pieces, which are alternately installed on the filter screen. The upper end of the filter screen is welded with a press plate, the lower end is welded with a base, the base is screwed with a nut, and the felt filter is pressed tightly on the upper end of the press plate through the lower tray.

The filter cover is screwed with an inlet and outlet oil pipe joint, and a cock of the discharge pipe, and an air drain nozzle is arranged on the cock.

The filter body and the filter cover are connected with a center rod, one end of which is screwed into the screw plug at the bottom of the filter body, and the other end is screwed with a nut to connect the two. The filter element is pressed on the filter cover by a spring mounted on the plug.

The fuel enters the inner cavity between the filter element and the housing from the inlet tubing 7, and then flows through the felt filter and silk sleeve into the inner cavity of the metal mesh and from here along the tubing to the outlet tubing. The tubing is installed for the purpose of absorbing clean and airless fuel, and the air is collected in the upper part of the filter. The drain plug is used to drain the air from the oil chamber to filter the air in the fuel. Air must be expelled from the diesel engine before starting.

Third, high pressure gap filter

Before the fuel enters the fuel injection nozzle, a high-pressure gap filter is also installed on many diesel engines for the last filtration. This filter by the grinding steel filter rod, with a small gap (about 0.02-0.04mm) inserted into the sleeve, in the filter rod milling 8-40 oil groove, half for the oil, the other half for the oil, the two mutually staggered, fuel from one end into, through the gap, from the other end out, so that some small impurities remain in the tank to achieve the purpose of filtration. And can extend the use of the nozzle time, but the fuel quality is good, this filter can work 400-500 hours after cleaning.

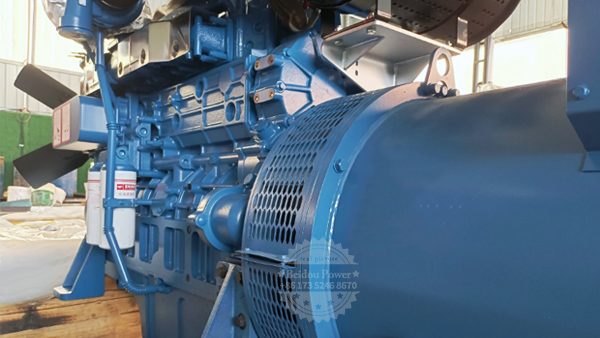

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Jan-06-2025