The air cooling system of a diesel generator set utilizes high-speed air flow to directly blow over the outer surfaces of the cylinder head and cylinder block of the diesel engine, dissipating the heat transferred from the interior of the cylinder into the atmosphere to ensure that the diesel generator set operates within a favorable temperature range.

The cylinders and cylinder heads of diesel engines are cast from aluminum alloy with good heat conduction. To increase the heat dissipation area, each cylinder is generally manufactured separately. Many evenly arranged heat sinks are distributed on the surface of the cylinders and cylinder heads to increase the heat dissipation area. By taking advantage of the high-speed air flow during the operation of the diesel engine, the heat is blown away into the atmosphere. Due to the large power of diesel generator sets, a considerable amount of heat needs to be cooled. Therefore, axial flow fans with greater power and flow rate are often used to enhance the cooling of diesel engines. In order to effectively utilize the air flow and ensure uniform cooling of each cylinder, baffles, deflector plates and cylinder liner deflector plates are installed on the diesel generator. Although air cooling systems have advantages such as simple structure, light weight, fewer malfunctions and no need for special maintenance compared with water cooling systems, they are rarely used in automobiles at present due to high material quality requirements, uneven cooling and high working noise. However, they are widely used in construction machinery.

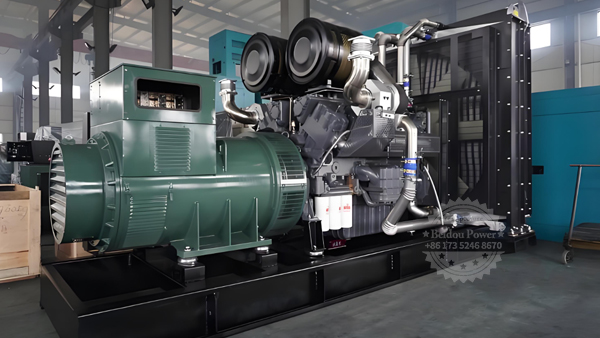

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Apr-21-2025