For the maintenance of diesel generator sets, the phenomenon of hard twisting fasteners with a wrench, or hard knocking fasteners with a hand hammer often occurs. As a result, the diesel engine broke down frequently after installation, and some even caused serious accidents. The important fastener assembly precautions on the diesel engine are described as follows, in order to attract the attention of the majority of machine operators and repair personnel.

1. Cylinder head nut. When tightening the cylinder head nut, it should be gradually tightened to the specified torque several times, and carried out according to the principle of first middle, after both sides, and diagonal cross. When removing the cylinder, it should also be gradually loosened in the prescribed order. If the cylinder head nut is tightened unevenly or imbalanced, it will cause the cylinder head plane warping deformation. If the nut is too tight, the bolt will stretch and deform, and the body and thread will be damaged. If the nut is not tight enough, it will cause air leakage, water leakage, oil leakage, and the high temperature gas in the cylinder will burn out the cylinder gasket.

2. Flywheel nut. For example, the flywheel and crankshaft of the S195 diesel generator are connected through cones and flat keys. When installing, the flywheel nut must be tightened and locked with a flanged thrust washer. If the flywheel nut is not screwed tightly, the diesel engine will produce a knocking sound when working, which will damage the crankshaft cone, shear the keyway, and twist the crankshaft, resulting in serious accidents. Also note that the thrust washer Angle can only be bent once.

3. Connecting rod bolts. The connecting rod bolts processed with high-quality steel can withstand great impact during work and cannot be replaced by ordinary bolts. The torque should be uniform when tightening, and the two connecting rod bolts should be gradually tightened to the specified torque several times in turn, and then locked with galvanized iron wire. If the connecting rod bolt torque is too large, it will make the bolt tensile deformation or even break, causing cylinder ramming accidents; If the tightening torque of the connecting rod bolt is too small, the clearance of the bearing shell increases, the knocking sound and impact load are generated during work, and even the accident of burning the tile and holding the shaft and breaking the connecting rod bolt occur.

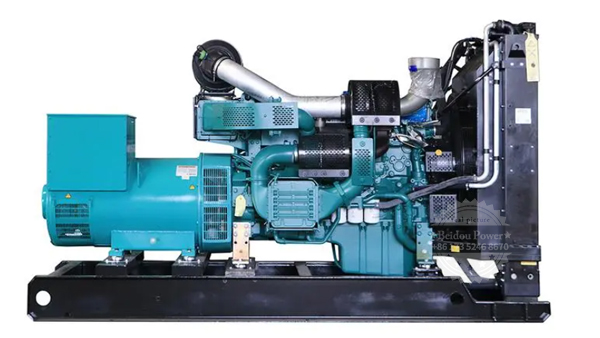

For more questions about the generator set, please call the Beidou Power team. More than ten years of professional production and sales of power generation equipment experience, more professional engineer team to serve you, choose Beidou power is to choose rest assured, welcome on-site factory inspection.

Post time: Nov-06-2024